WELCOME VISIT WENZHOU XIANGHAI MACHINERY

Polypropylene high Speed Flat Yarn Extruder Machine with inverter control Winder Woven sack Production Line

Insist---Concentration---Innovate---Service

Constant innovation and beyond just to create higher value for you!

Constant innovation and beyond just to create higher value for you!

Polypropylene high Speed Flat Yarn Extruder Machine with inverter control Winder Woven sack Production Line

.jpg)

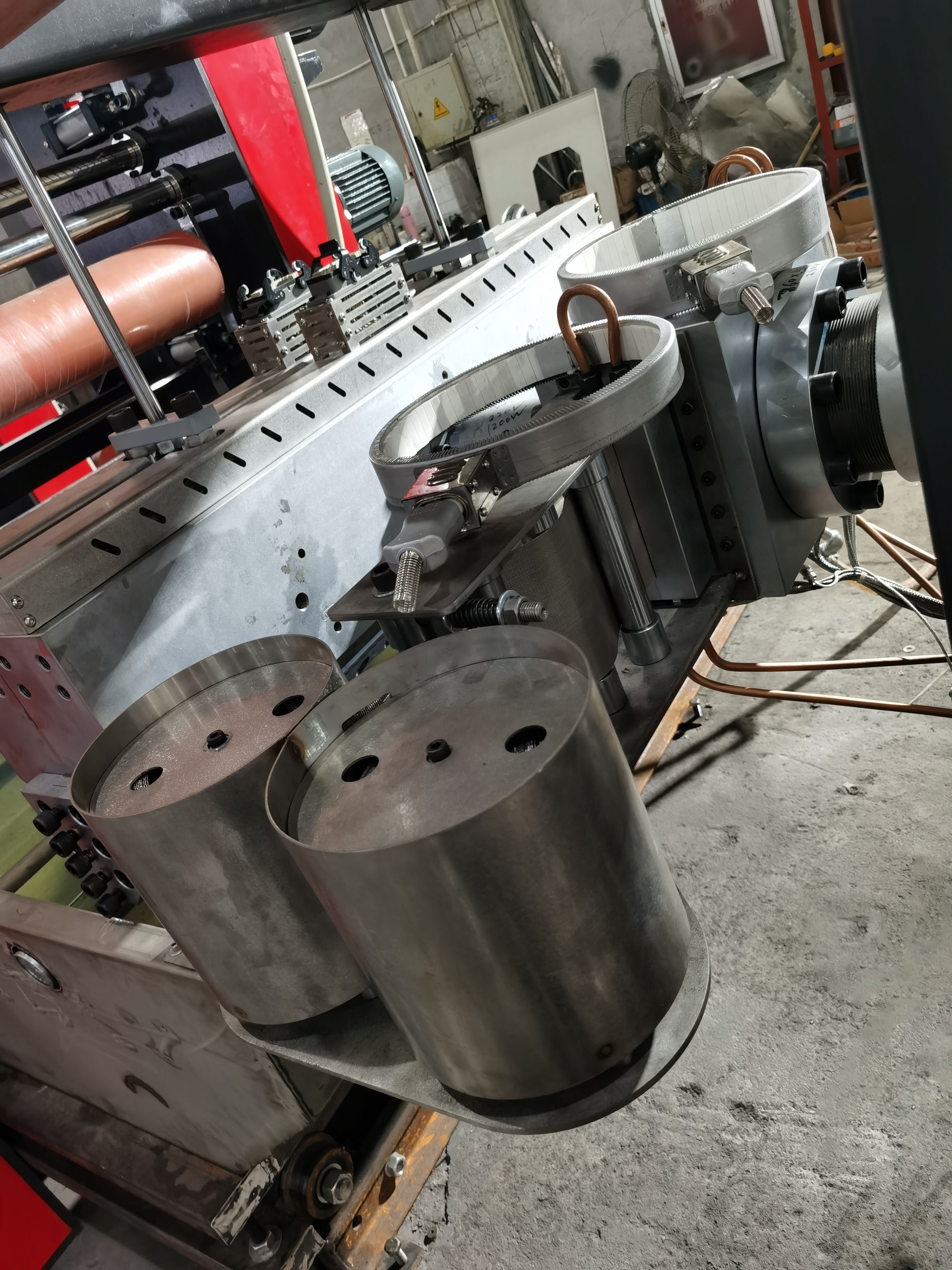

The stretching line is adopted micro-processor control, frequency conversion governor and setting and displaying technical data may be fully digitized on the basis of absorbing international advanced techniques. The main parts use quality products. The line enlarges L/D ratio and adopts new type of separating screw and widens mixing smelt zone on the extruder screw pot which is specially processed using quality steel, fine plasticized effect, low energy consumption in relation to output. For the change filter system of the flat film stretching line, we apply advanced automatic belt change filter. The bake-board is changed into advanced hot drawing oven and principal technical index of the line reaches international advancing level. The winding machine is of friction-free drive and constant tape tension wind, good formation quality of the fiber drum. The line has the performance of high speed, top yield, low energy consumption, good forming quality of the fiber drum. The structure of the line is compact with a pleasing appearance, smooth running, flexible and reliable control, sophisticated manufacture engineering, convenient operation and reliable production; it can be used in producing flat fiber form thermoplastic, such as polypropylene (PP) and high-density polyethylene (HDPE) etc.

The tape stretching line is consists of an extruder, a screen changer, a die, a water quench system, a film take-off and slitting film into tapes device, a traction system, a hot air oven, a stretching and annealing unit, a winding unit, edge tape and waste tapes reclaim system as well as electric control cabinet, etc.

.jpg)

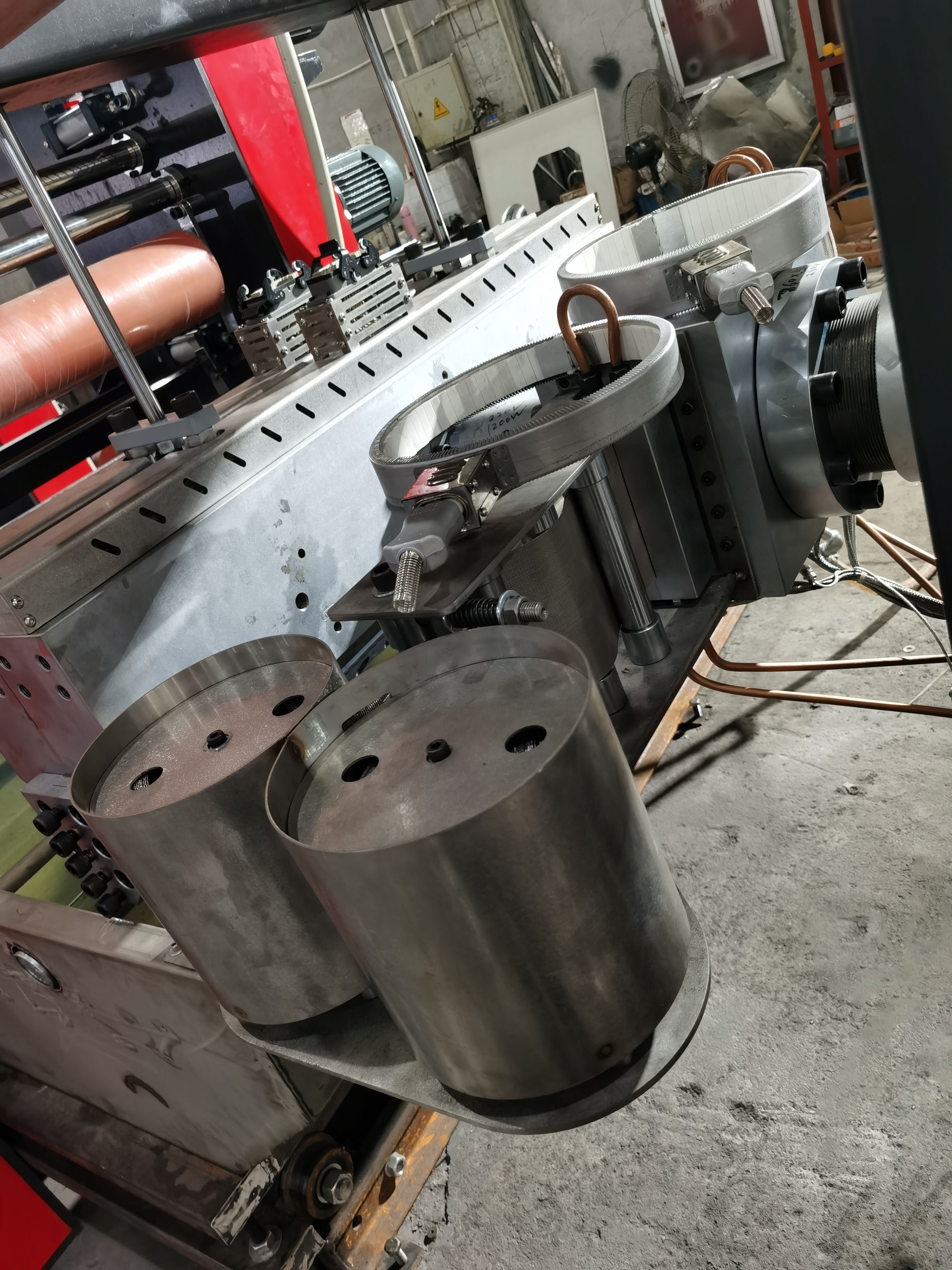

The stretching line is adopted micro-processor control, frequency conversion governor and setting and displaying technical data may be fully digitized on the basis of absorbing international advanced techniques. The main parts use quality products. The line enlarges L/D ratio and adopts new type of separating screw and widens mixing smelt zone on the extruder screw pot which is specially processed using quality steel, fine plasticized effect, low energy consumption in relation to output. For the change filter system of the flat film stretching line, we apply advanced automatic belt change filter. The bake-board is changed into advanced hot drawing oven and principal technical index of the line reaches international advancing level. The winding machine is of friction-free drive and constant tape tension wind, good formation quality of the fiber drum. The line has the performance of high speed, top yield, low energy consumption, good forming quality of the fiber drum. The structure of the line is compact with a pleasing appearance, smooth running, flexible and reliable control, sophisticated manufacture engineering, convenient operation and reliable production; it can be used in producing flat fiber form thermoplastic, such as polypropylene (PP) and high-density polyethylene (HDPE) etc.

The tape stretching line is consists of an extruder, a screen changer, a die, a water quench system, a film take-off and slitting film into tapes device, a traction system, a hot air oven, a stretching and annealing unit, a winding unit, edge tape and waste tapes reclaim system as well as electric control cabinet, etc.

.jpg)